LORD Dynaflex Driveline Couplings - LCR Series

Part # LCR-400-800-115A

Part # LCR-400-800-115A

LORD Dynaflex LCR Series Couplings are ring type couplings developed to overcome numerous torsional problems associated with vehicular and industrial driveline systems. These highly flexible couplings are also designed to eliminate lubrication and maintenance.

Additional Images

| Torque Rating | 3600 lbs - in / 407 N - m | ||||||||||||

| Per 100 RPM | 5.71 HP / 4.26 kW | ||||||||||||

| Capacity (1750 RPM) | 100.0 HP / 74.5 kW | ||||||||||||

| Capacity (2000 RPM) | 114.2 HP / 85.2 kW | ||||||||||||

| Capacity (3600 RPM) | 205.6 HP / 153.3 kW | ||||||||||||

| Static Torsional Rate - K |

46000 lb - in/rad / 5197 N - m/rad | ||||||||||||

| Axial Rate KA | 3600 lb/in / 630 N/mm | ||||||||||||

| Radial Rate - K R | 6400 lb/in / 1121 N/mm | ||||||||||||

| Permissable Misalignments (Angular) | +/- 2° | ||||||||||||

| Permissable Misalignments (Axial) | +/- 1/16 in / 1.59 mm | ||||||||||||

| Permissable Misalignments (Parallel) | +/- 1/64 in / 0.40 mm | ||||||||||||

| Weight | 1.25 lb - Mass / 0.567 kg | ||||||||||||

| Inertia | 0.0072 lb - in - sec / 814 kg - mm2 | ||||||||||||

| No. of Inserts | 8 | ||||||||||||

| Part No. | LCR-400-800-060A | LCR400800060A | ||||||||||||

| Manufacturer | LORD Corporation | ||||||||||||

| Part Category | Vibration Control | ||||||||||||

| Part Section | Dynaflex Couplings | ||||||||||||

| Part Type | Dynaflex Couplings - LCR Series Couplings | ||||||||||||

| Part Status |

|

||||||||||||

| Part Alternative |

|

||||||||||||

| Catalog Page No. |

|

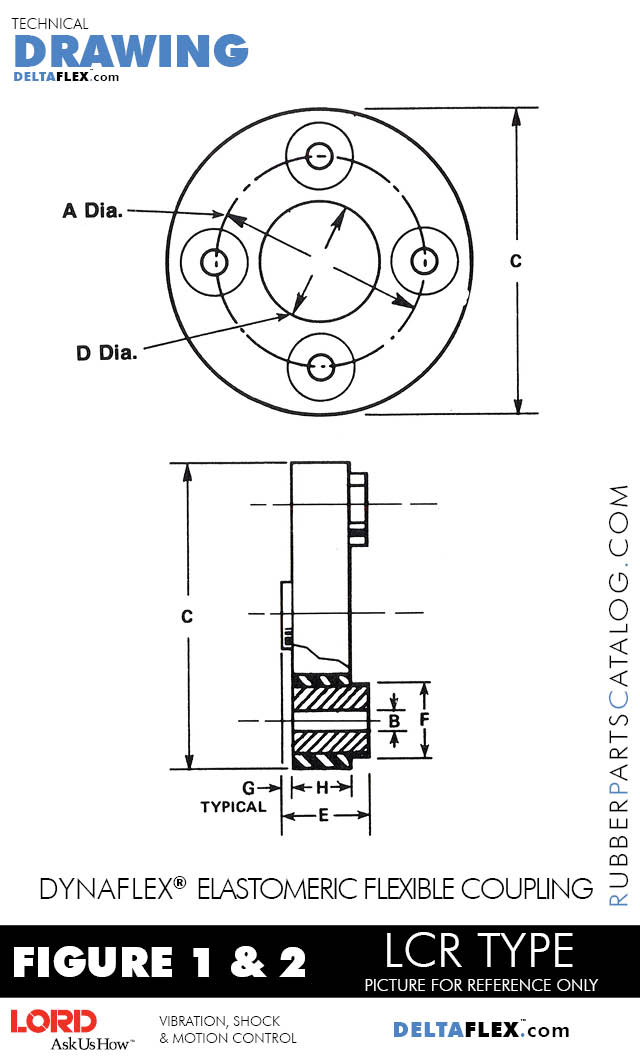

| Dimensions | Technical Drawing | ||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

NOTES: Red figures are metric reference. Torque Requirements: Torque (lb - in) = 63025 x hp NOTE - * - See detail drawings by part number for tolerances.

|

***Notes only apply if called out in table*** NOTES

|

Features and Benefits

- Misalignment Accomodation - Elastomeric flexibility allows for larger angular misalignment. For permissible misalignments, including axial and radial, Refer to Table 1

- Vibration Isolation - Low torsional spring rate is achieved with the elastomeric ring-type coupling using rubber in compression.This allows for low system natural frequencies and isolation of first mode driveline disturbances in most driveline systems.

- Shock Protection - Isolates torsional shock, prevents backlash and protects system components, including bearings, from fatigue failure.

- Long Service Life - Dynaflex LCR Series Couplings have proven themselves under demanding service conditions.

- Maintenance Free - Elastomer flexibility accomodates all motion without wear, eliminates the need for lubrication.

- Noise Reduction - No metal-to-metal contact; elastomer attenuates structure-borne noise and isolates vibration from components that would act as noise generators.

- Systems Engineering - LORD has in-house computer capabilities for multi-torsional analysis to assist in proper coupling selection.

NOTE - * See detail drawings by part number for tolerances.

NOTES: Red figures are metric reference.

LORD does not supply hubs. LORD supplies ring elements only.

Torque Requirements:

Torque (lb - in) = 63025 x hp

rpm

NOTE - * - See detail drawings by part number for tolerances.

NOTES

- Torque ratings as listed are maximum steady torques per application requirements. For general applications, dynamic torques of +/-35%of the coupling rate torques can be applied to the listed torque ratings. Shock (e.g. , start-up torque, etc.) of up to 200% rated torque are generally acceptable.

- Does not include bolts or flanges

Custom Designs

Customized designs and special elastomer compounds for specific problems are available. These may result in spring rates and dimensions other than shown.

A part’s listing on this website does not guarantee its availability.

Custom Parts

Our custom molding department can make a part just for your application.

Engineering

Would you like some assistance in selecting the right mount for your application? Our engineering department can help. Please call or use the webform below. We will be glad to assist.

Not what you are looking for?

Our knowledgeable staff can assist you with whatever you need. From Special Packaging, Overnight shipments to applications engineering. DeltaFlex is ready to help find a solution.

Engineering Assistance

"Frequently vibration isolation problems require a system engineering analysis..." - Put us to work for you.

DeltaFlex has the computer capability, as well as specialized programs, for analyzing engine/transmission combinations. The output from these analyses is a mounting proposal which optimizes performance over the complete range of operating speeds. This service is available to you upon request. If you require this type of engineering assistance please call 800.657.0747 we will be glad to assist you.

What is the impact of Vibration Control?

The biggest impact that vibration isolation can have, is with the end users of our customers products, more importantly their perception of the quality of those products.

Values states herein represent typical values as not all test are run on each lot produced. For formalized product specifications or specific product end uses, contact Customer Service 262.632.2345.

A part’s listing on this website does not guarantee its availability.