LORD RUBBER SHEAR TYPE DRIVELINE COUPLINGS

Horsepower Rated: 1/50 hp to 1 hp at 1750 rpm

"For Low Frequency Vibration Isolation and Misalignment Accommodation"

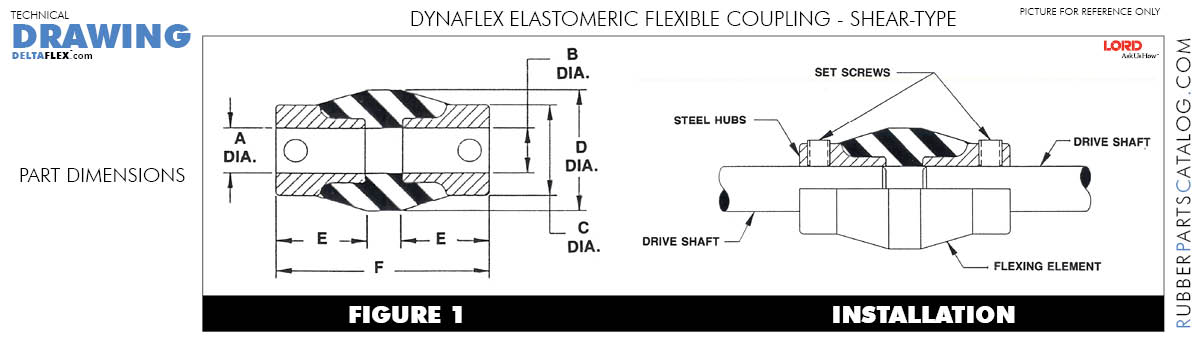

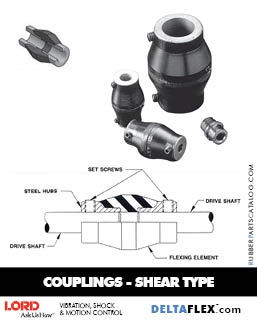

LORD Dynaflex® Shear-Type Couplings are compact, one-piece flexible couplings economically constructed to isolate low-frequency vibration and accommodate multidirectional misalignment.

Features

- 1/50 to 1 hp @ 1750 rpm

- Rubber coupling for fractional horsepower

- High Torsional Deflection

- Versatile Application Potential

- Combination Misalignment Accommodation

- Easy Installation

- One Piece Construction

- No Lubrication or Maintenance

Typical Applications

- Information Systems – Motor drive, printer rollers, indexing devices, linear actuator, drives and card sorters

- Hospital Bed – Actuator drive

- Dynamometer – Driveline

- Tachometer – Driveline

- Pumps, Blowers, Compressors – Driveline

These couplings reduce the adverse effects of transient shock torques, torsional vibration, noise and misalignment associated with small equipment drivelines. This results in longer service life, smoother, quieter operation, less maintenance, and lower cost for your end product.

Shear-Type flexible couplings are useful in many small equipment driveline applications. Multi-directional misalignment capabilities make them ideally suited for fractional horsepower drivelines demanding noise reduction, vibration isolation and maintenance-free operation.

Features & Benefits

|

|

|