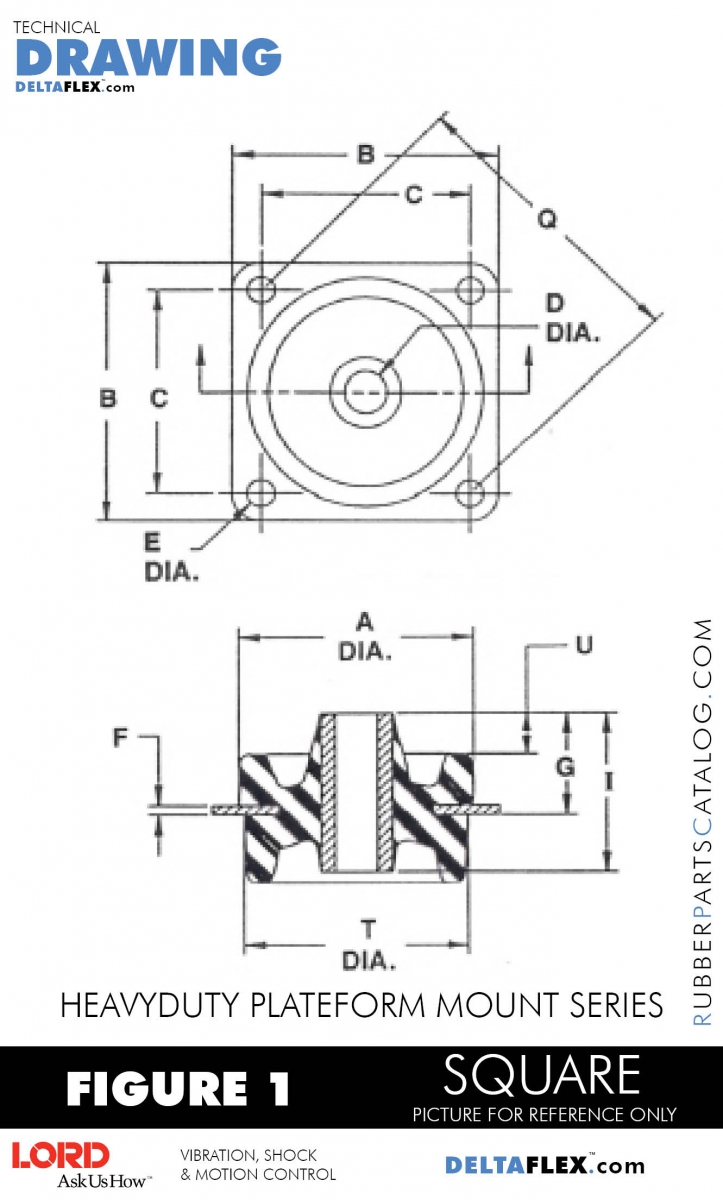

Square | LORD Heavy-Duty Plateform Mount

Part # 283P-220

Part # 283P-220

LORD Heavy-Duty Plateform Mounts provide effective isolation against vibration. The contour of the flexing element was developed to provide uniform stress distribution. This, plus high strength bonding and the use of specially compounded elastomers, provides maximum service life.

Additional Images

| Max Axial Rated Load | 220 lbs. / 979 N | ||||||||||||

| Axial Spring Rate | 880 lbs./in. / 154.1 N/mm | ||||||||||||

| Part No. | 283P-220 | 283P220 | ||||||||||||

| Manufacturer | LORD Corporation | ||||||||||||

| Part Category | Vibration Control | ||||||||||||

| Part Section | Plateform Mounts | ||||||||||||

| Part Series | Heavy-Duty Plateform Series | ||||||||||||

| Part Type | Square | ||||||||||||

| Snubbing Washer | J-2049-4 (see Accessories Tab for more info) | ||||||||||||

| Part Status |

|

||||||||||||

| Part Alternative |

|

||||||||||||

| Catalog Page No. |

|

| Dimensions Under No Load | Technical Drawing | ||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

| NOTE: Red figures are metric reference. |

Snubbing Washers

Snubbing washers provide an interlocking system of metal parts which act to prevent damage from overload or excessive shock impact. Steel washers are plated.

| Series No. | Part No. | O.D | I.D. | Thickness |

| 283 | J-2049-4 | 2.88 in. (73.2 mm) | 0.52 in. (13.2 mm) | 0.125 in. (3.2 mm) |

Notes: Red figures are metric reference.

Tolerances

0.xx = ± 0.03 in. (± 0.762 mm) 0.xxx = ± 0.015 in. (± 0.381 mm)

Mounting bolt holes are + 0.005 in. ( 0.127 mm ) and - 0.002 in. (0.050 mm)

Isolation Performance

Refer to Engineering Guide, Sample Problems section for a step by step method to calculate system natural frequencies and isolation efficiency.

Materials

Metal parts are cold rolled steel or alodized aluminum alloy. Flexing elements are specially compounded natural rubber. Steel holders for holder-type mountings are plated. Unplated steel parts are coated with specially prepared rust preventative for protection during shipment or storage.

Smaller Loads

For loads under 120 lbs. (534 N) use a Plateform Series Mount.

Radial Spring Rate

Radial spring rate is approximately two to three times the listed axial spring rate.

Custom Designs

Customized designs and special elastomer compounds for specific problems are available. These may result in spring rates and dimensions other than shown.

A part’s listing on this website does not guarantee its availability.

Custom Parts

Our custom molding department can make a part just for your application.

Engineering

Would you like some assistance in selecting the right mount for your application? Our engineering department can help. Please call or use the webform below. We will be glad to assist.

Not what you are looking for?

Our knowledgeable staff can assist you with whatever you need. From Special Packaging, Overnight shipments to applications engineering. DeltaFlex is ready to help find a solution.

Engineering Assistance

"Frequently vibration isolation problems require a system engineering analysis..." - Put us to work for you.

DeltaFlex has the computer capability, as well as specialized programs, for analyzing engine/transmission combinations. The output from these analyses is a mounting proposal which optimizes performance over the complete range of operating speeds. This service is available to you upon request. If you require this type of engineering assistance please call 800.657.0747 we will be glad to assist you.

What is the impact of Vibration Control?

The biggest impact that vibration isolation can have, is with the end users of our customers products, more importantly their perception of the quality of those products.

Values states herein represent typical values as not all test are run on each lot produced. For formalized product specifications or specific product end uses, contact Customer Service 262.632.2345.

A part’s listing on this website does not guarantee its availability.